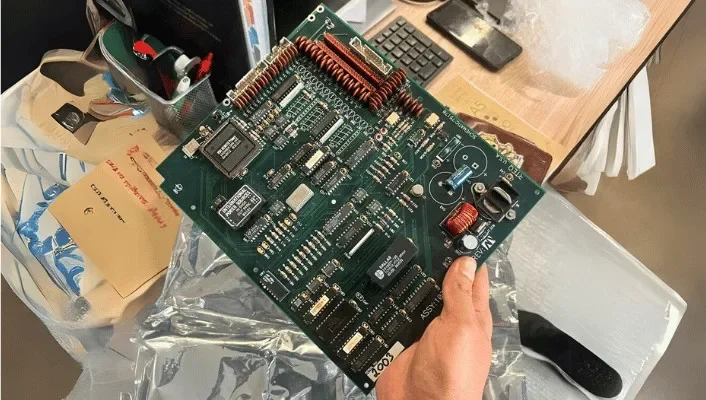

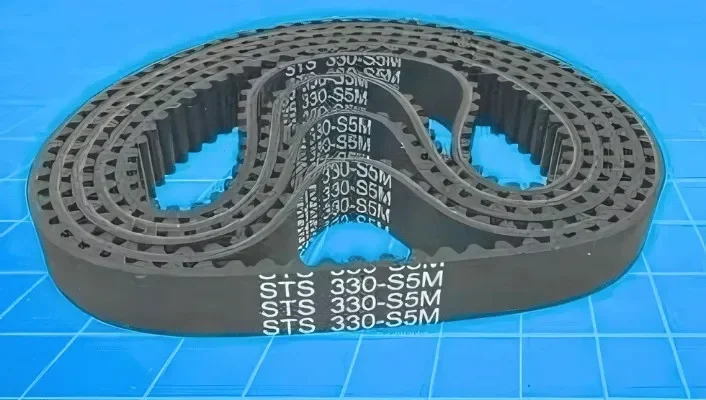

This project aims to create a precision parts cleaning facility for our clients based in the Northern Region (Penang, Kedah etc.) and cater to their part cleaning needs.

Currently there is only one specialised facility in Kulim that can do this service. We aim to provide a second option and enter the market.